Documents

Bevel helical gearbox

| Exceptionally long service life | High efficiency | Modular system | |||

| High proctection class | Low noise |

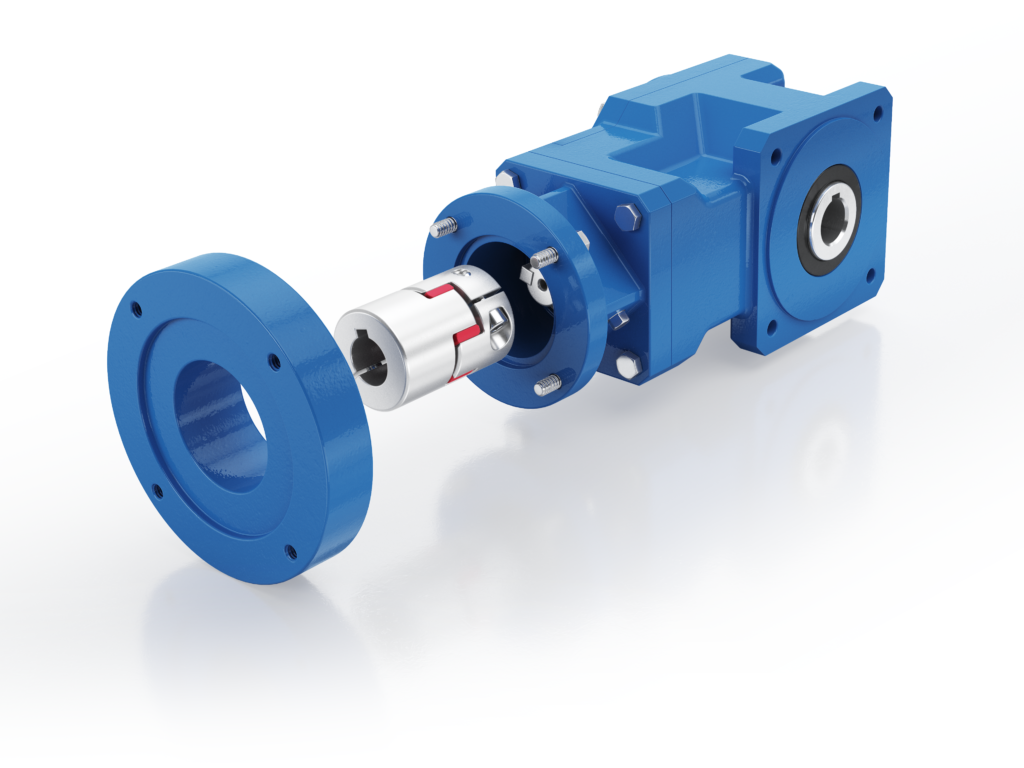

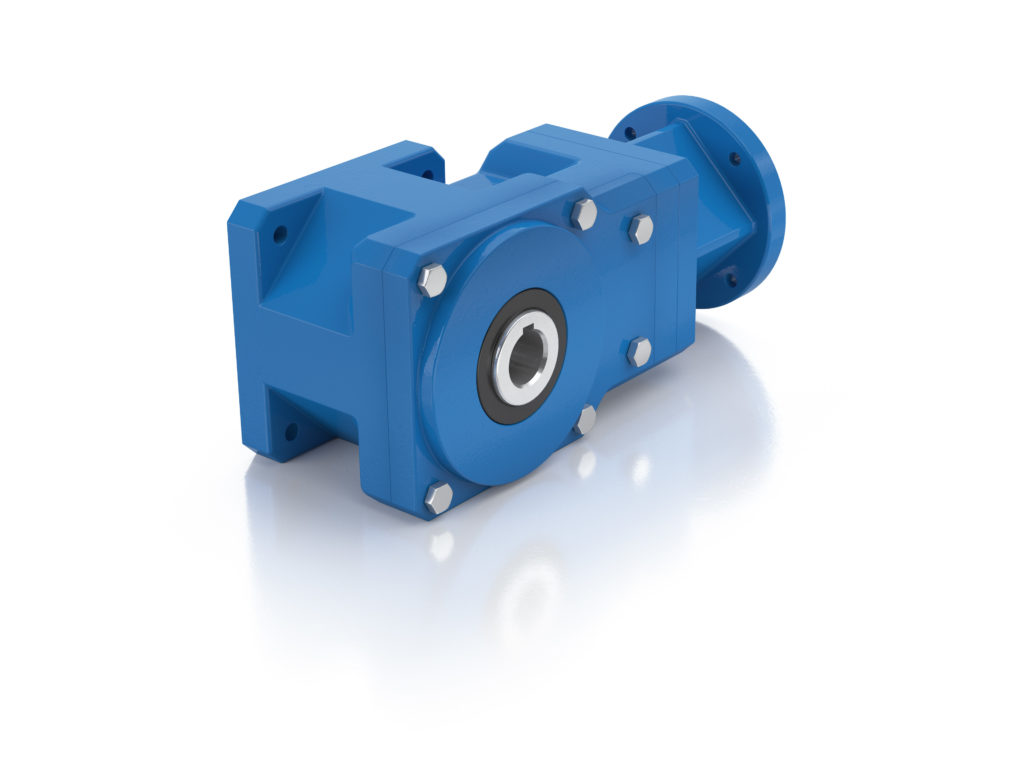

Our bevel-helical gearbox KS210 is designed as a compact drive unit for highly-dynamic applications. The requirements for operation with servomotors have been implemented accordingly. During the development, attention was also paid to high operational reliability by generously dimensioned bearings and toothing design. Furthermore, the housing with an integrated square flange on the output side offers maximum rigidity and can be universally installed or attached thanks to the symmetrical inline housing. The drive is available with a solid or hollow shaft (if required with an optional clamping set). The output shafts are also optionally available in stainless steel or even with surface protection matched to your application.

A stainless steel housing (stainless steel gear, hygienic drive, wash-down application) is available for particularly high surface quality requirements.

Requirements placed on new gear concepts were taken into account. Minimal circumferential backlash, high rigidity, low overall weight, high efficiency, maximum flexibility in connection with a universal mounting position are features that allow the successful usage of the drive.

Characteristics

Options

Areas of application

Performance data

Illustrations, dimensions and representations are non-binding. Illustrations show options.Technical changes reserved.